Aerospace Contacts is committed to Quality.

You may be assured that your custom contacts and connector products are thoroughly tested and inspected at every stage of the production process. Through continuous improvement in key manufacturing processes, process control, and a complementary range of inspection, mechanical testing and materials testing, Aerospace Contacts is committed to quality.

Aerospace Contacts makes quality a top priority and has a robust quality management system which includes the following:

Quality Policy: “Aerospace Contacts is committed to providing precision machined quality products that meet or exceed customer requirements through the continual improvement of the quality management system.”

Certifications:

Compliance:

-

- ITAR Registered and ITAR Compliant

- DFARS Compliant

- AMS 2750 Compliant for heat treating

- F0736 Supplier Quality Codes

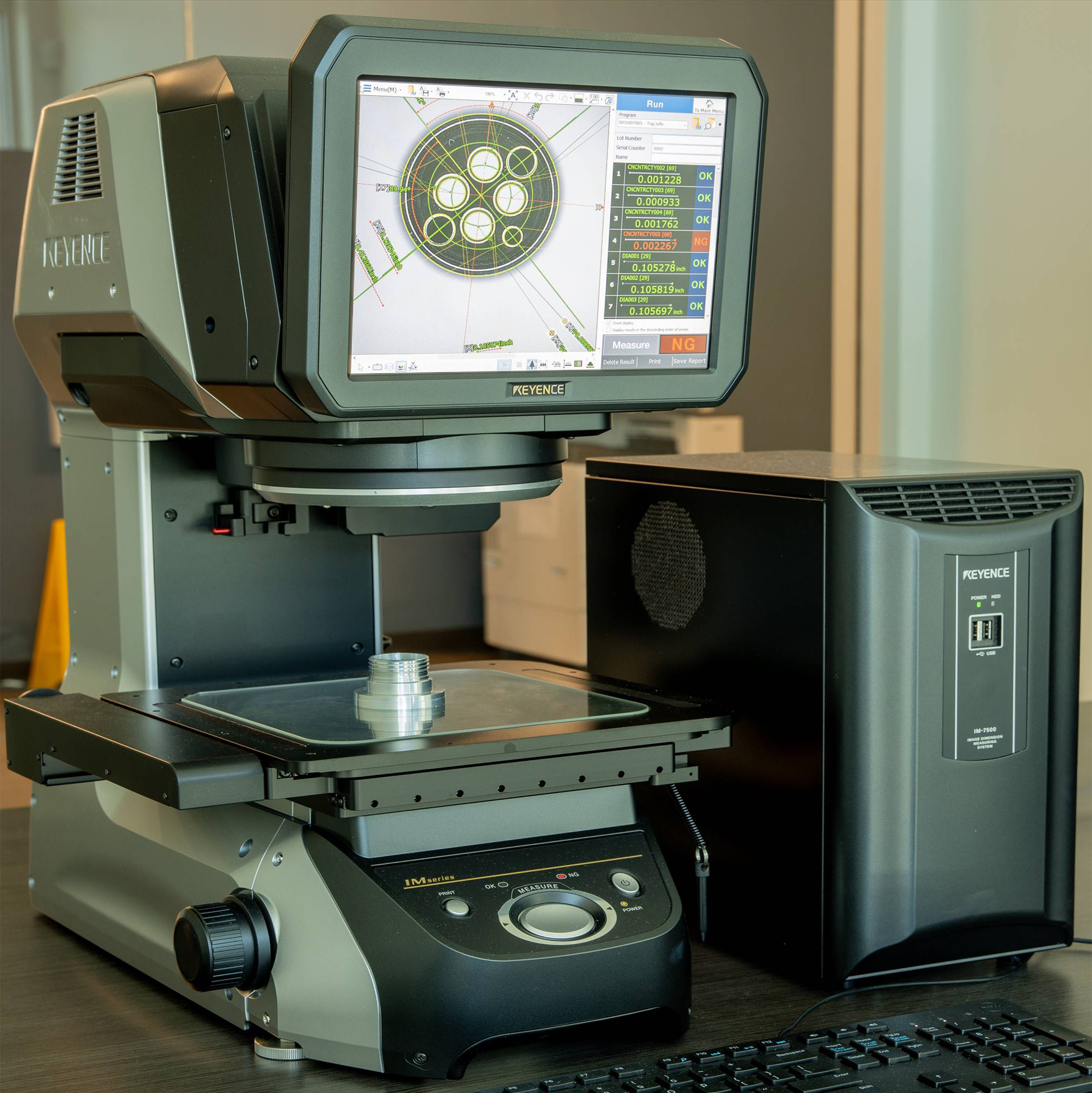

Inspection & Testing Capabilities

- All orders/shipments include a standard FAIR

- First Article Inspection Reports (FAI)

- Customer-specific inspection offerings

- AS9102 FAIR

- Cp/Cpk Capability Studies

- Control Plans, pFMEA

- Full mechanical dimensional inspection

- Laser micrometer

- Keyence vision systems

- Optical comparators

- Toolmaker microscopes

- Functional testing

- Force Testing (sockets)

- Pull testing (hoods)

- Micro hardness testing

- Tensile testing (crimp barrels)